Surge arrester is described by NEC as a protective device for limiting surge voltages by discharging or bypassing surge current on an electrical system to earth or ground. It also prevents continued flow of follow current while remaining capable of repeating these functions. In other words, a surge arrester’s purpose is to protect equipment or the system from damage due to transients.

In the past, they are known as lightning arresters due to the fact that they were primarily designed to protect equipment from lightning strikes. Nowadays, the term surge arrester has been more widely used since the device is actually effective against both lightning and switching transients.

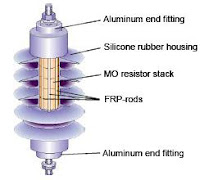

|

| Surge Arrester (Distribution Class) |

Basic Operation

Surge arresters are mainly composed of nonlinear resistive devices whose resistance decreases as the implied voltage increases. The drop in resistance continues until the surge arrester functions just like a direct short to ground. Consequently, the transient or surge is diverted to ground away from the protected equipment. Therefore, the negative effects of surges are minimized or even eliminated.

Arrester Classes

1. Secondary Class

It is commonly installed to protect equipment at the utilization voltage level and is available in ratings up to 650 V.

2. Distribution Class

This type is usually applied to protect distribution system equipment (i.e. distribution transformer, capacitor banks).

3. Intermediate Class

It offers an improved protective characteristics and durability compared to the distribution class. This type is typically used for the protection of medium class power equipment and smaller substations.

4. Station Class

It gives the best protective level and is capable of diverting the most energy. Generally, it is use for applications where premium protection is needed such as generators and large substations. It is also the most expensive class of arrester.

In deciding which class of arrester to install, the main considerations are the importance of the equipment being protected and the cost.

Arrester Technology

Surge Arrester technology has undergone radical changes. A century ago, spark gaps were used to suppress transient overvoltages. Nowadays, there are two types of arresters based on the material employed as their nonlinear conductive element:

1. Silicon Carbide (SiC)

In the 1930s, silicon carbides replaced the spark gaps. SiC uses nonlinear resistors composed of bonded silicon carbide placed in series with gaps. The gaps function to isolate the resistors from the normal steady-state system voltage. These gaps are its main disadvantage as complicated designs are needed to guarantee a reliable spark-over level and positive clearing after a transient event.

In 1976, Metal Oxide Varistors began to replaced Silicon Carbides for arrester applications. MOV surge arresters make use of zinc-oxide blocks to provide the best performance and superior protection, as surge voltage conduction starts and stops quickly at a precise voltage level. These arresters are without gaps (gapless), unlike the SiC arrester. This design eliminates the high heat associated with the arcing discharges and as a result, failures are minimized as there is no air gap contamination. Subsequently, a small but negligible value of leakage current is present when normal voltage is applied. The MOV arrester has become preferrable because of its simplicity and relatively lower cost.

Duty Cycle

This rating is determined by the so-called duty cycle testing. The process involves subjecting the arrester to RMS AC voltage equal to its rating for 24 minutes, during which it must withstand lightning surges at one-minute intervals. The test uses the 8/20μs surge waveshape (i.e. the current wave reaches its peak in 8 ms and drops to half the crest value in 20 ms). The surge magnitude is 5 kA for both the intermediate and distribution class arresters, while station class types are subjected to 10 kA.

Maximum Continuous Operating Voltage (MCOV)

The MCOV rating (for MOV type only) is typically 80% to 90% of its duty cycle rating. This is the recommended magnitude limit of the applied voltage that the MOV surge arrester could continuously operate . Exceeding the MCOV, will subject it to a higher-than-recommended temperature and may lead to a shortened life or premature failure.

References:

Hill, K. (2004). Surge Arresters and Testing

IEEE C62.1-1989. Standard for Gapped Silicon-Carbide Surge Arresters for AC Power Circuits

IEEE C62.11-2005. Standard for Metal-Oxide Surge Arresters for AC Power Circuits (>1 kV)

McDermott, T. (2007). Power Systems

No comments:

Post a Comment